Five Things You May Not Know About Carbon Fiber

Updated October 20221. Not all Carbon Fiber Is Created Equal

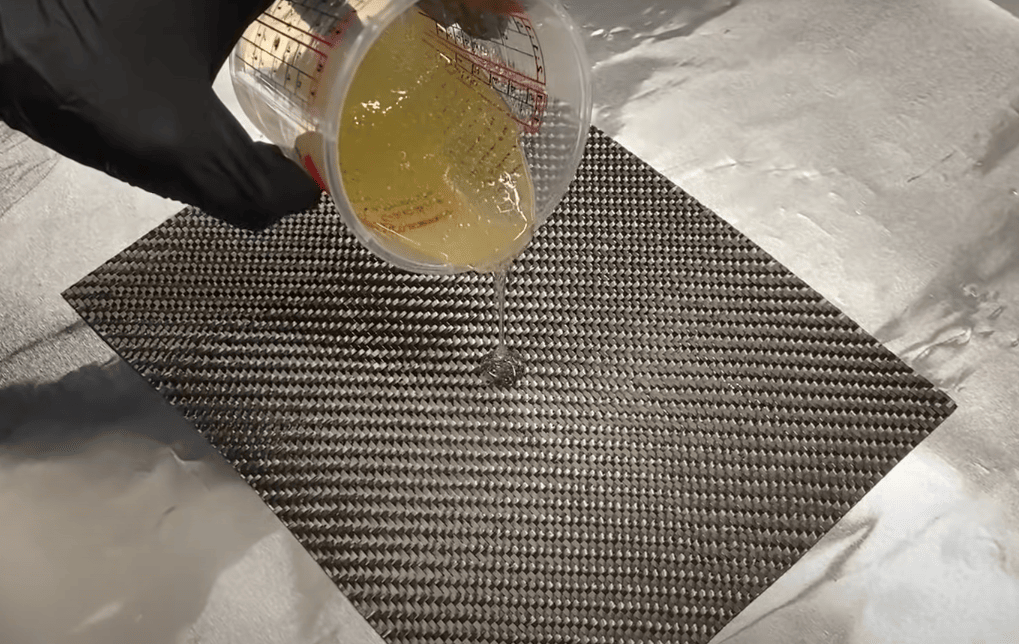

Most carbon fiber parts start out as a dry cloth, which gets combined with a liquid resin. The resin cures to form a solid polymer, allowing the cloth to hold its shape and become a rigid carbon fiber part. The first thing to know about carbon fiber is that not all carbon fiber is created equal. This statement is not in reference to the different fabric weave types or the fiber counts like 3k, 6k, or 12k, but rather the fiber grade and the quality of the cloth itself.

Carbon fiber is commonly sold as a roll of woven cloth. There are many different cloth weave patterns to choose from to fit different applications. The cloth itself is made up of fiber bundles called “tows” that are woven or stitched together. Within each fiber bundle are individual carbon fiber filaments that are smaller than a human hair. These filaments are categorized according to their grade. The grade is a big part of what determines the strength and stiffness of a carbon fiber part. Carbon fiber manufacturers like Toray and Hexcel offer a range of different fiber grades with different strengths and stiffnesses.

Carbon fiber is commonly sold as a roll of woven cloth. There are many different cloth weave patterns to choose from to fit different applications. The cloth itself is made up of fiber bundles called “tows” that are woven or stitched together. Within each fiber bundle are individual carbon fiber filaments that are smaller than a human hair. These filaments are categorized according to their grade. The grade is a big part of what determines the strength and stiffness of a carbon fiber part. Carbon fiber manufacturers like Toray and Hexcel offer a range of different fiber grades with different strengths and stiffnesses.

At the lower end of the spectrum is “commercial grade” carbon fiber, which is quite common. It is typically the lowest cost, but it also has lower strength and stiffness compared to higher grade carbon fibers. A chart of different carbon fiber grades from Toray is shown below. Their T300 grade, highlighted in orange, is often considered a commercial grade fiber.

It is common to use higher grade carbon fibers that are stronger and stiffer when making parts for aerospace applications like aircraft, rockets, or satellites. Several fibers that are often used in aerospace applications are highlighted in green in the chart below.

Each fiber manufacturer has their own nomenclature for their carbon fiber so pay close attention when selecting a cloth. Different fiber grades from Hexcel and Toray are highlighted in green in the charts below.

The quality of the cloth is also important. The quality is a measure of the number of defects in the cloth. A defect can be anything from broken or frayed strands to weave imperfections like gaps or skips in the weave pattern. Higher grade cloths limit the number of defects, while lower grade or second grade cloths allow for a higher number of defects.

The quality of the cloth is also important. The quality is a measure of the number of defects in the cloth. A defect can be anything from broken or frayed strands to weave imperfections like gaps or skips in the weave pattern. Higher grade cloths limit the number of defects, while lower grade or second grade cloths allow for a higher number of defects.

Because not all carbon fiber is created equal, it is critical to know the grade of the fiber and the quality of the cloth, especially in structural applications.

Understanding fiber grades and cloth quality is exciting because it allows for better optimization of parts. For example, parts can be made stronger and stiffer without increasing their weight. In the case of the DarkAero 1, this meant creating an aircraft with a lighter airframe with more useful load available for carrying people, luggage, and fuel.

2. RESIN IS AS IMPORTANT AS THE Fiber

As mentioned earlier, carbon fiber starts out as a dry cloth, and it can only become a rigid part by being combined with a resin in the form of a composite material. The proper term for the resin component of a composite material is actually the “matrix material” or just the “matrix”, but for this article it will be referred to as resin. A simplified analogy would be to compare carbon fiber composite to concrete and rebar. The fibers carry tensile loads similar to rebar, and the resin allows the cloth to hold its shape and carry compressive loads similar to concrete. A bridge or a building would not be built out of just concrete or just rebar. Both are needed to achieve the full strength required in a structure.

As mentioned earlier, carbon fiber starts out as a dry cloth, and it can only become a rigid part by being combined with a resin in the form of a composite material. The proper term for the resin component of a composite material is actually the “matrix material” or just the “matrix”, but for this article it will be referred to as resin. A simplified analogy would be to compare carbon fiber composite to concrete and rebar. The fibers carry tensile loads similar to rebar, and the resin allows the cloth to hold its shape and carry compressive loads similar to concrete. A bridge or a building would not be built out of just concrete or just rebar. Both are needed to achieve the full strength required in a structure.

In the case of a carbon fiber part, the same is true. Without resin, rigid carbon fiber parts could not be created. In that sense, the resin is the true unsung hero in any carbon fiber part, and selecting the right resin is just as critical as selecting the right carbon fiber.

It is important to not become fixated on the carbon fiber alone and then forget about what resin type will be used. One example illustrating the importance of resin selection comes from the development history of the DarkAero 1. High temperature capability was one of the performance requirements for the resin systems used in the aircraft, and testing was performed to validate candidate materials. One resin was tested that claimed to maintain strength up to 300F, but when it was tested at high temperatures, it would soften and allow parts to bend at temperatures as low as 200F. The carbon fiber was doing its job, but the resin was not. This test demonstrated that a carbon fiber part can fail when the wrong resin is selected. The important takeaway is to pay attention to resin just as much as the carbon fiber grade and fabric quality.

It is important to not become fixated on the carbon fiber alone and then forget about what resin type will be used. One example illustrating the importance of resin selection comes from the development history of the DarkAero 1. High temperature capability was one of the performance requirements for the resin systems used in the aircraft, and testing was performed to validate candidate materials. One resin was tested that claimed to maintain strength up to 300F, but when it was tested at high temperatures, it would soften and allow parts to bend at temperatures as low as 200F. The carbon fiber was doing its job, but the resin was not. This test demonstrated that a carbon fiber part can fail when the wrong resin is selected. The important takeaway is to pay attention to resin just as much as the carbon fiber grade and fabric quality.

3. CARBON FIBERS CAN BE COATED TO IMPROVE ADHESION

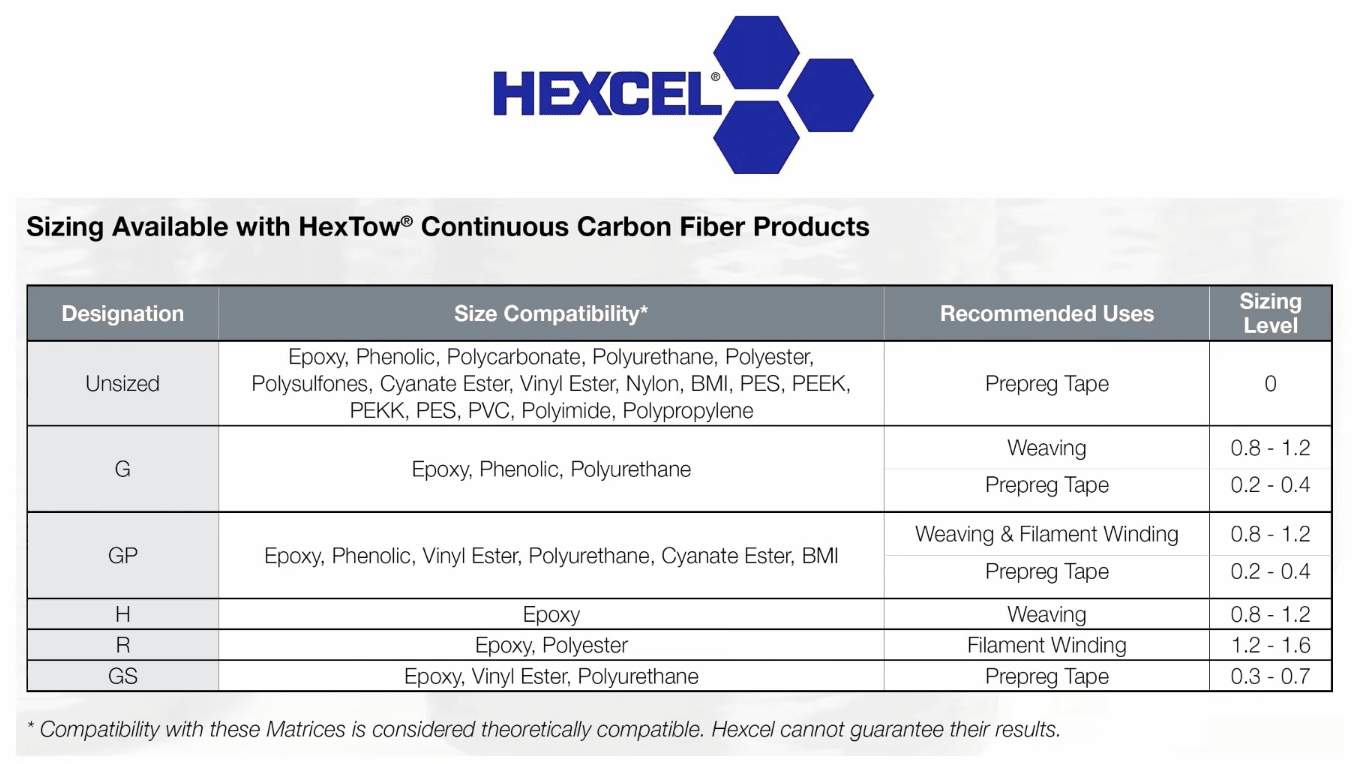

Carbon fiber manufacturers add special coupling agents (also referred to as a “finish” or “sizing” agent) to their fabrics to help the resin adhere to them. Depending on what resin is selected, it might not want to wet out the carbon fiber and chemically bond to it. This is similar in principle to how oil and water will not mix. This same situation would be undesirable when combining carbon fiber and resin, so a coupling agent is applied to the fibers to allow the two materials to work together.

The specific chemistry of coupling agents is often kept secret by the carbon fiber manufacturers. They will obscure the specific coating and instead will only disclose the general chemistry the coating is compatible with. An example highlighting coupling agent compatibility is shown in the Hexcel chart above. Keep the coupling agent in mind when experimenting with unconventional matrix materials.

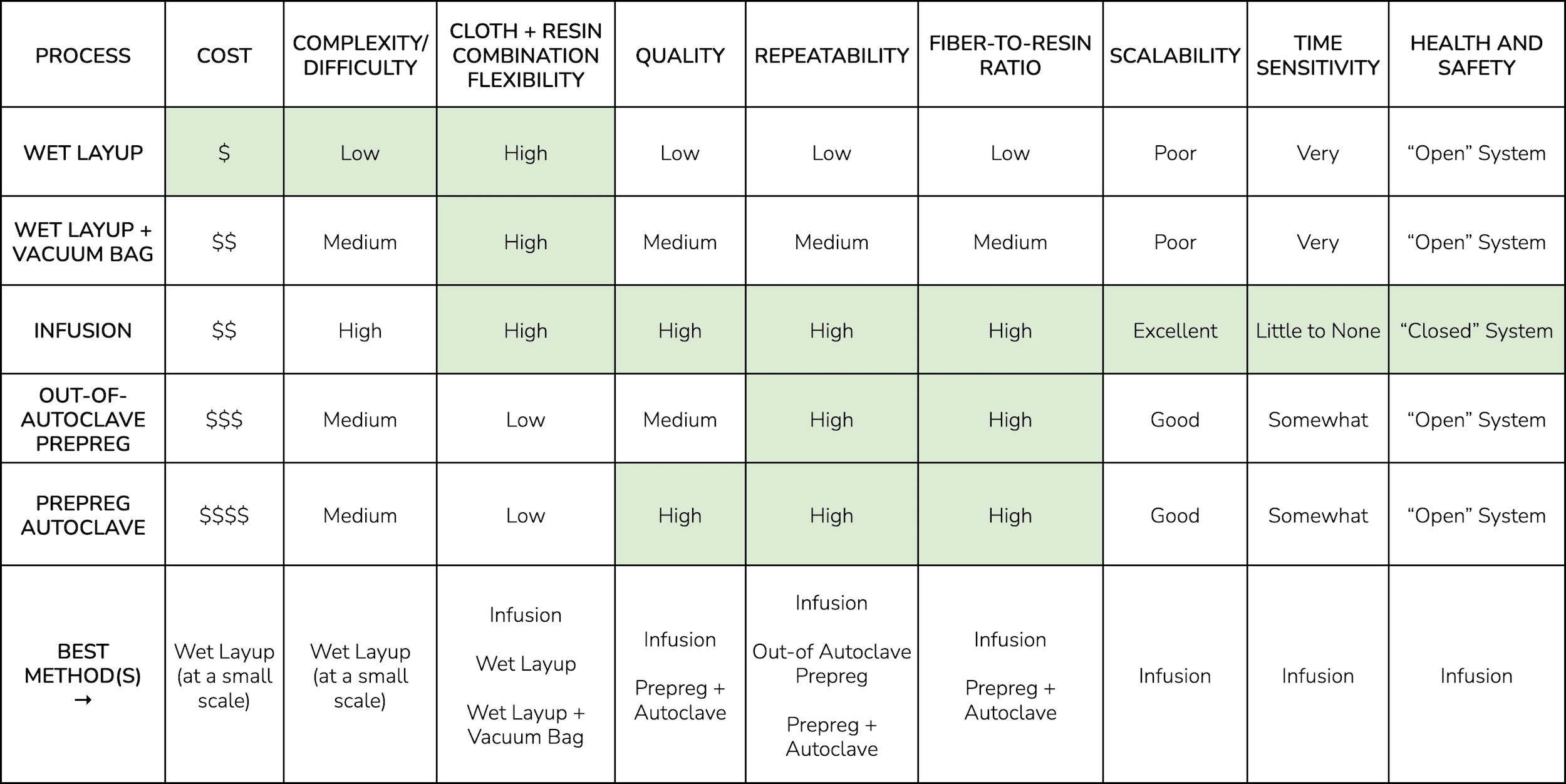

4. Process Determines Properties

There are many different ways of making carbon fiber parts like wet layup, infusion, prepreg, or even 3D printing. These methods will all make parts with different fiber to resin ratios and different amounts of defects, which will result in different strength and stiffness properties in the final part. The temperature that the part is cured at also affects the properties of the final part.

There is no official “best” approach to making a carbon fiber part. The best method really depends on the design of the part and the manufacturing goals. There are pros and cons for each method.

For example, wet layup is low cost and easy to do, but it usually results in parts that have inconsistent physical properties and are typically heavier compared with other composite manufacturing techniques.

Prepreg carbon fiber can produce high-quality, light parts, but this method often requires more costly tooling like storage freezers and autoclaves. There are also fewer resins and weave combinations to pick from. The prepreg resin also has a shelf life, which means that prepreg material can expire and must be discarded if it is not used within its shelf life

Infusion is used to create the carbon fiber parts on the DarkAero 1 because it produces repeatable results with fiber-to-resin ratios similar to prepreg and achieves a high-quality surface finish. Examples of this surface finish can be seen in the parts below.

The important thing to keep in mind is the process picked to combine carbon fiber and resin will partly determine the properties of the final part.

5. Physical Testing is Critical

Carbon fiber isn’t like metal. Metals are generally isotropic, meaning they have the same properties in all directions, which simplifies design and analysis. In addition, measured mechanical properties are well established for common metal alloys.The same can not be said for composites due to their limited standardization and the broad range of material and process variables in composites. This means testing needs to be conducted to verify that composite parts meet their desired requirements.

In the aerospace realm, one of the best ways to conduct testing on composites is by following the “building block approach”. This method begins by testing generic coupons and elements to create a database of material properties. This data is used to drive the design and testing of larger components, then sub-assemblies, and finally complete structures. Each test article must be representative of the materials and process used in the final structure.

There is a misconception that carbon fiber parts can be validated through simulation alone. Analysis tools such as Finite Element Analysis (FEA) can help guide composite part design, but they rely on material property inputs that must be accurate in order to achieve reliable results. The best way to obtain accurate numbers for these input variables is through physical testing on representative composite test samples. Without accurate inputs, analysis results will have limited utility. Large safety margins must be added to a design to account for unrefined quantification of material properties. This adds weight, ultimately defeating one of the main reasons composite materials are selected in the first place. Thus, there really is no way to completely eliminate physical testing from the design process of an optimized composite structure.

There is a misconception that carbon fiber parts can be validated through simulation alone. Analysis tools such as Finite Element Analysis (FEA) can help guide composite part design, but they rely on material property inputs that must be accurate in order to achieve reliable results. The best way to obtain accurate numbers for these input variables is through physical testing on representative composite test samples. Without accurate inputs, analysis results will have limited utility. Large safety margins must be added to a design to account for unrefined quantification of material properties. This adds weight, ultimately defeating one of the main reasons composite materials are selected in the first place. Thus, there really is no way to completely eliminate physical testing from the design process of an optimized composite structure.

The amount of work involved in all this testing might seem excessive, but if testing is not performed in the beginning, the design will still be put to the test in service, which is a bad time to find out if it’s going to fail.

Video: Carbon Fiber - 5 Things You Probably Didn't Know

Learn More

If you’d like to learn more about how to consistently make high-quality composite parts and get hands-on experience working with carbon fiber, consider enrolling in one of our courses:Aerospace Composites Course

Aerospace Mold Making Course

The courses are structured as a mix of both classroom lessons and hands-on demonstrations in the shop. Composite material fundamentals, design methods, material and process selection, and design for manufacturability are covered in class. Examples specific to student applications are used to immediately apply what is learned. Online versions of both courses are available as well at the links below:

Aerospace Composites Online Course

Aerospace Mold Making Online Course